Jump to:

Controlling a 7-Axis Robot for Continuous Internal Bore Welding

Gas tungsten arc welding (GTAW) is not commonly used in robotics because the process is erroneously believed to be too slow or complicated for robotics. But technological advances are changing that.

GTAW is great when a project requires precise, high-quality welds, and it works on a range of base metals for joining and cladding. Although most welding robots are used for resistance welding and others are for gas metal arc welding (GMAW), many joining and cladding projects are better suited for GTAW.

Distinctive Aspects of Robotic GTAW

Welding speed or productivity is measured in pounds per hour of metal deposited. To make GTAW as fast and productive as GMAW requires using the hot wire technique. The filler wire is preheated as it enters the weld pool using an independent hot wire power supply. The hot wire technique improves productivity and decreases dilution, both key for clad overlay welding.

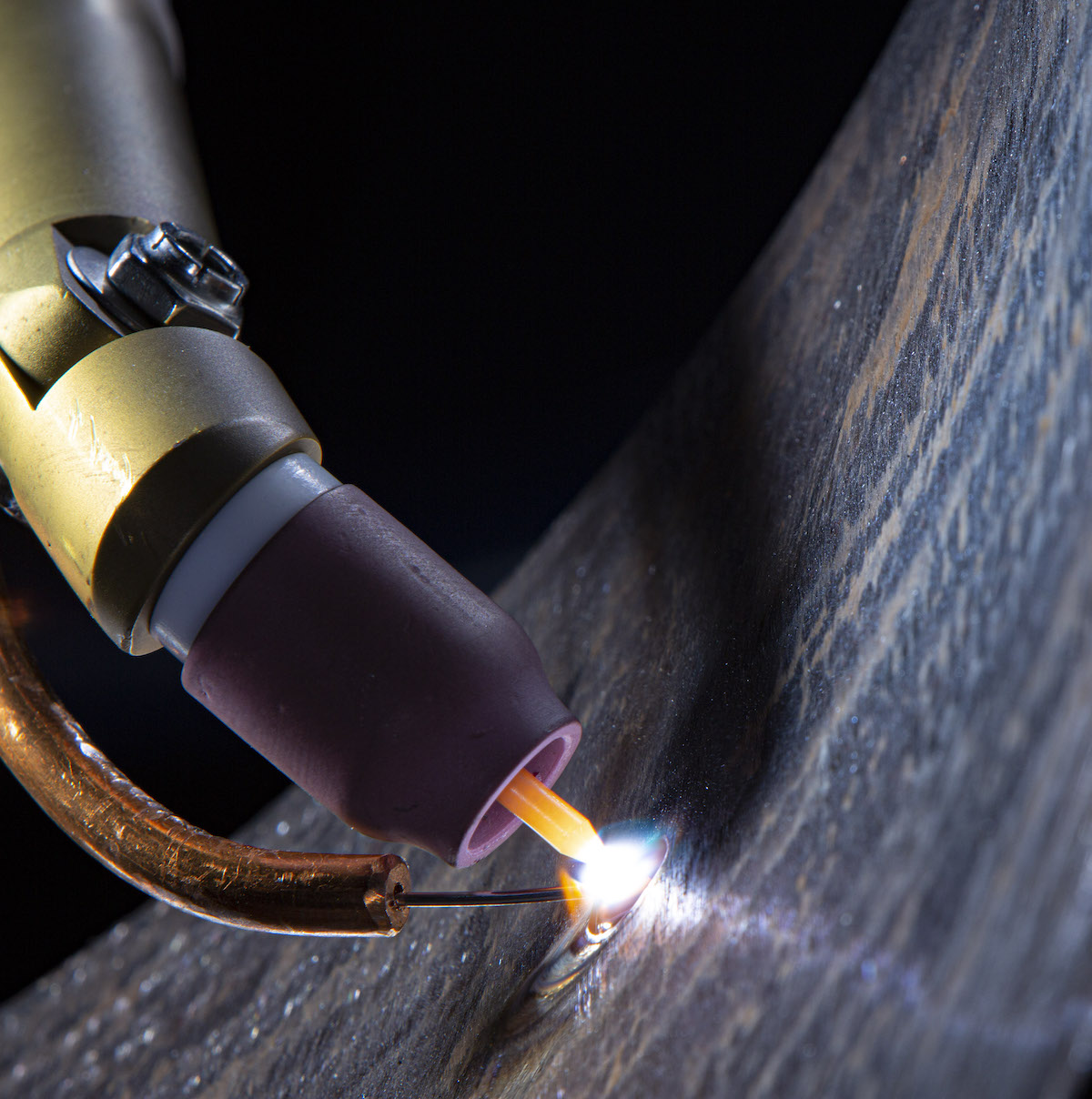

Making GTAW work on robots requires some unique features. Automatic torch height control is essential. Arc length is also critical. Typically held around 1/8 ± 0.01 in., the robot must follow the surface of the workpiece by monitoring and maintaining constant arc voltage. Simultaneously, the robot must position the wire to feed into the trailing edge of the weld pool. Dedicating one axis of the robot for wire positioning limits robot flexibility. Finally, bore cladding requires continuous torch rotation, which creates cable wrap-up. Advanced controls and new hardware solve these issues.

Paying Attention to Corrosion

Corrosion comes in many forms. In the oil industry, hydrogen-induced cracking (HIC) has caused expensive and catastrophic failures. HIC results when sour crude oil containing > 0.5% hydrogen sulfide (H2S) reacts with the iron in valves and pipes, releasing atomic hydrogen. When atomic hydrogen migrates into the grain boundaries of steel parts, intergranular cracks form and parts fail due to internal stress. For decades, a solution was to overlay weld all the internal wetted surfaces of valves, fittings, and pipes exposed to H2S. More recently, there's been a move to hot wire GTAW and nickel alloy welding wires resistant to H2S corrosion. High part preheat temperatures; deep, small diameter parts; and stringent inspection criteria make internal cladding an ideal candidate for automation.

Axis Attention

6-axis robots are becoming less expensive and more capable. Robots are replacing purpose-built machines with flexible robotic automation. But 6 axes and standard arc welding controls are not enough for hot wire GTA bore cladding. Continuous rotation bore clad welding requires an additional axis, multiple welding power supplies, and very different software.

The newest generation of GTAW hot wire clad systems leverage the latest in robot technology. A 6-axis KUKA robot, integrated with ARC Specialties’ ARC-5 Infinity 7th axis robotic cladding system, allows infinite rotation of the torch inside of a stationary part. Utilizing 4 × 4 homogenous transformation matrices to calculate the kinematics of the 7thaxis allows precomputing of the absolute positions of the robot with 6 deg of freedom, based upon the head rotation. The software compares the robot’s absolute Cartesian position with the calculated Cartesian points while safely limiting the allowable travel every 4 ms. Using high-speed EtherCAT® communication, the controller updates the KR C4 control system 250 times per second. The dimensions of the part, as well as the commanded arc voltage and head rotation, determine the position of the robot in real time during the entire welding sequence.

Orbital welding is challenging. Within every revolution, the system must constantly correct the torch position not just up and down but relative to the direction of the torch. It is preferable to use all 6 axes of the robot to move the torch along its centerline.

In addition, welding intersecting internal bore requires hundreds of arc starts and stops, each of which requires several lines of software. The preferred programming answer is to teach four points at the bore intersections then use parametric programming software to generate the part program automatically. It seamlessly compensates for preheat expansion, variations in first layer welds, and any part positioning or fixturing issues.

Enhancing Welding Parameters

The ARC-5 Infinity can weld bores in any orientation. Welding anything other than a vertical bore has unique challenges because gravity affects the weld pool differently depending on the weld's location. Within each revolution, the system must weld flat, vertical, and overhead. The traditional solution is slow and unproductive. A better way is to optimize welding parameters as the weld position changes to produce a weld with consistent shape and size for the complete 360 deg around the part. With modern control systems, constant real-time updating of welding parameters improves productivity.

Conclusion

Recent advances in hardware and software allow robots to GTA weld in many industries. Robotic system integrators are also making robot GTAW accessible and practical for applications that benefit from the precision and quality inherent to the GTAW process.

This article was written by Dan Allford (president), John Martin (vice president), and Zach Freeman (automation programmer), all of ARC Specialties, Houston, Tex., for the American Welding Society.